PRODUKTS:

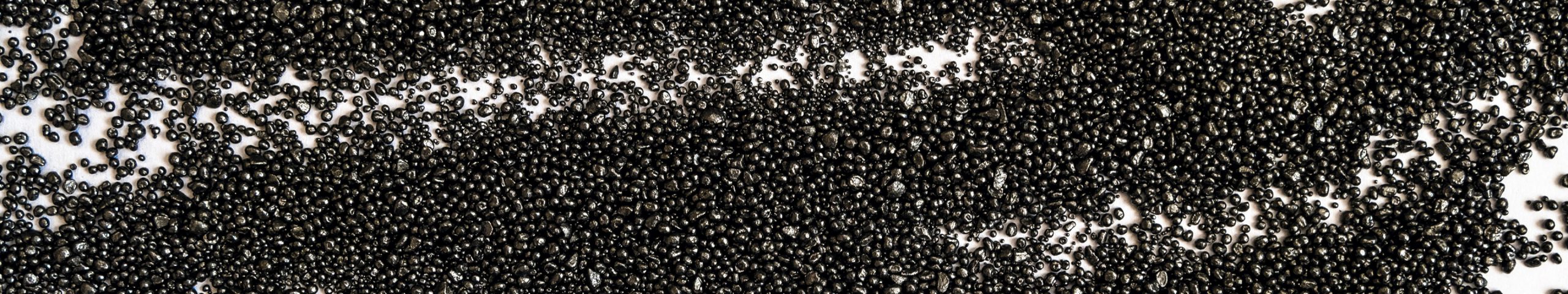

HIGH PERFORMANCE PLASTICS

High Performance Plastics offer a variety of advantages and are an usuable alternative to metal or ceramic.

High Performance Plastics are polymers which have excellent mechanical, thermal and electrical characteristics. A high temperature range from over 150°C, an excellent sliding friction, high chemical resistance and low weight make these plastics attractive.

Characteristics of these plastics:

- Permanent operating temperature from 150 to. approx. 300°C

- Good chemical resistance, also at high temperatures

- Good mechanical strength

- High dimensional stability

- High creep resistance in a wide temperature range

- Good hydrolysis stability

Application area:

- Electronic parts: connectors, plugs, contact rail, heat protection, coil carrier,…

- Automotive – „under the hood“, fuel & braking systems,…

- Medical technology: surgical instruments,…

- Household application: microwave dishes,…

- Engineering: Parts for compressors and pumps, gears, cog wheels, valves, bearings, chain guides,…

- Chemical technology: fittings, valves, bush bearings, pump parts, nozzles, pipes, rolls,…

- Airplane and Space technology